14 January 2026

The Profit Paradox: Is Your Web-to-Print Strategy Scaling Your Margin - or Eroding It?

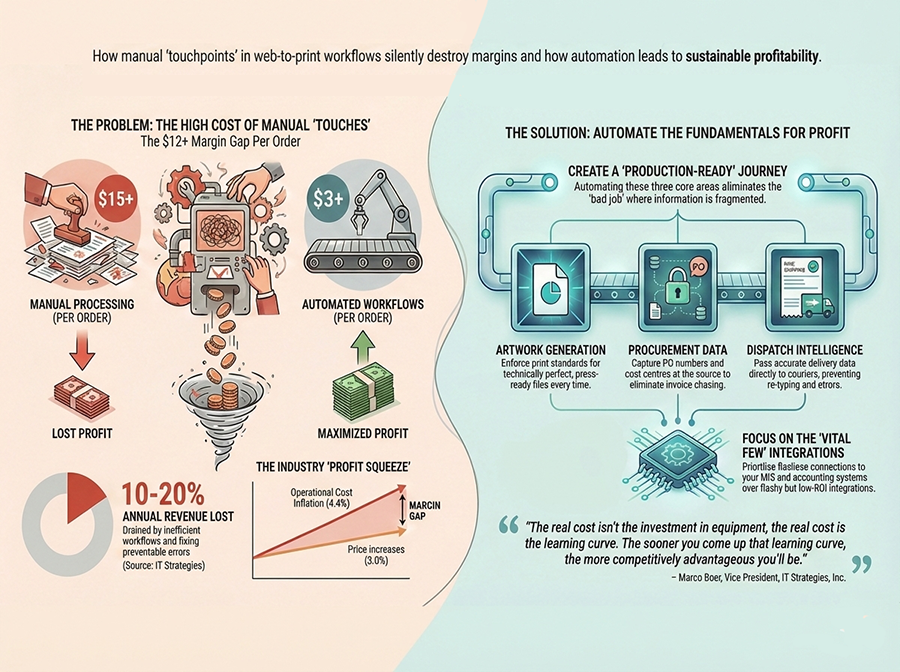

Whether your Web-to-Print (W2P) strategy is scaling your margin or silently eroding it depends on how much manual effort remains hidden behind your storefront. As we move through 2026, the industry has reached a critical tipping point. According to the PRINTING United Alliance State of the Industry Report 2025, sales remained flat or declined for 62.8% of commercial printers, creating a landscape where "growth" is no longer guaranteed by volume alone. The answer lies in Mastering the Fundamentals of digital automation; by removing the "invisible" manual touches that plague every order, you can turn administrative overhead into pure profit.

The US industry is currently locked in a relentless "profit squeeze." Operating cost inflation-driven by persistent labor shortages and material costs - is currently averaging between 2.9% and 5.0%, while market pricing power has lagged behind at just 2.1% (Source: PRINTING United Alliance / Technavio 2025). This gap means that simply "selling more" is a failing strategy if your cost-per-job remains high. To protect your bottom line in 2026, you must move beyond the "shiny" front-end features of W2P and adopt a platform that automates the entire transition from the customer’s procurement desk to your production floor.

________________________________________

The $12 Gap: The Hidden Cost of Manual Touchpoints

Every time a staff member has to intervene in a job - whether to fix a file, chase a PO, or re-type a shipping address - your margin evaporates. Industry benchmarks from the Institute of Finance & Management (IOFM) and Resolve Pay show that manual administrative processing typically costs between $15 and $16 per order.

When a workflow is automated through a competent Web-to-Print (W2P) system, those costs drop to as low as $3 per job.

Industry Insight: Inefficient manual workflows and reworks caused by preventable errors are estimated to drain 10–20% of a print provider’s annual revenue (Source: IT Strategies / Printing Impressions). For an agile printer, recovering this "lost" revenue is the fastest way to fund growth without increasing headcount.

________________________________________

The Integration Trap: Don’t Get Distracted by 'Shiny' Features

Many W2P providers sell on the "wow factor" of hundreds of complex integrations - connecting to obscure marketing tools or niche social platforms. While these sound impressive in a tender, they are often a Loss of Focus.

Peripheral integrations often take months to set up, require constant IT maintenance, and deliver tiny marginal wins. The reality is that you are better off picking the most important integrations to your business and not getting distracted by periphery setups that end up taking a huge amount of time to deliver almost zero ROI.

The Pragmatic Approach

The most profitable printers focus on Operational Excellence. They don't try to integrate with everything; they integrate perfectly with the vital few systems that drive their business - primarily their MIS, accounting software, and their major clients' procurement systems. A platform that executes these fundamental connections flawlessly 100% of the time is infinitely more profitable than a platform that does 100 "cool" things unreliably.

________________________________________

Mastering the Fundamentals: Where the Money is Made

Where does the real margin increase happen? It is in the "Production-Ready" journey. Success isn't just about a "good file"; it's about avoiding the "bad job" where prepress must manually marry artwork with fragmented production information.

- Guaranteed Production-Ready Artwork: To protect margins, a workflow must enforce rigorous standards before a file ever reaches the press:

- Automated Technical Accuracy: Automatically manage bleeds, color profiles, and font integration to eliminate manual pre-flighting.

- Metadata Integration: Ensure every file carries the exact specifications your equipment needs for immediate processing.

- Error Prevention: Removing these manual "touches" at the start prevents the delays and reprints that erode profit.

- Procurement Data Accuracy: Accounts need to know which cost center or PO to invoice against before the job starts. By capturing this data at the source, you eliminate the "chase" at the end of the month.

- Dispatch Intelligence: Dispatch teams need to get the product delivered to specific customer requirements without re-typing addresses. Locking this in at the point of order ensures 100% accuracy.

________________________________________

The Real Cost of the Learning Curve

It is common for printers to hesitate over the complexity of new software. However, as Marco Boer, President of IT Strategies, points out, the risk of waiting is a loss of competitive standing.

Automation is a key to driving consistency in a manufacturing process... The real cost isn't the investment in equipment; the real cost is the learning curve. The sooner you come up that learning curve, the more competitively advantageous you'll be compared to your peers.

Marco Boer, President, IT Strategies, Inc.

By mastering these fundamentals now, you ensure that your business is the one setting the pace in tenders, offering a level of consistency and data-driven reliability that unautomated competitors simply cannot match.

________________________________________

How Vpress Solves the Efficiency Gap

Vpress doesn't just provide a storefront; we provide an end-to-end "Operational Engine" that removes the friction from every stage of the job lifecycle.

1. Unified Procurement Data and Automated Invoicing

Manual data entry is the primary cause of billing disputes and delayed payments.

- The Vpress Solution: Whether a user enters data directly into Coreprint or orders flow through an upstream integration (like a corporate procurement portal), Vpress captures all essential procurement information upfront.

- The Result: We provide comprehensive reporting and feed this data directly into your back-office MIS or ERP system. This allows for accurate, automated invoicing that matches your customer's internal requirements perfectly, ensuring you get paid faster with zero manual reconciliation.

2. Dispatch Accuracy and Logistics Integration

Shipping is often an administrative bottleneck where errors lead to costly reprints or lost packages.

- The Vpress Solution: Coreprint captures specific delivery instructions and shipping requirements at the point of order. This data is passed directly to your warehouse or courier systems.

- The Result: We eliminate "swivel-chair" data entry, ensuring 100% accuracy in dispatch and providing real-time tracking for the end-user without any intervention from your team.

3. Technically Perfect, Production-Ready Jobs

A "good file" isn't enough; you need a production-ready job.

- The Vpress Solution: Coreprint enforces strict print standards at the point of creation. It generates technically perfect artwork - complete with correct bleeds, color spaces, and font embedding - paired with the metadata your press needs.

- The Result: Jobs flow directly to the RIP or prepress queue. For more examples of how this transforms operations, you can explore our Success Stories.

4. Scalability for the Agile Printer

The most significant benefit of mastering these fundamentals is the ability to scale.

- The Vpress Solution: By automating the high-frequency, low-value tasks that bury your admin team, Vpress allows you to handle 10x the order volume without adding 10x the staff.

- The Result: This levels the playing field, allowing smaller, agile printers to target and win massive corporate contracts by proving they have the digital infrastructure to deliver reliably at scale.

________________________________________

Conclusion: Turning Dollars into Significant Sums

If you get the fundamentals right and scale them with volume, saving just a few dollars in administrative labor per job quickly amounts to significant annual sums. This is capital for growth. By focusing on doing the basics really well, you protect your margin and ensure every order is contributing to a healthy bottom line.

________________________________________

About Vpress

With over 25 years of innovation in print procurement technology, Vpress is a leading provider of Web-to-Print and workflow automation solutions. Our technology is designed to deliver measurable commercial returns by improving operational efficiency, enabling sustainable scalability, and strengthening customer retention. At Vpress, partnering with our customers for long-term success isn't just a marketing message - it is the principle that underpins everything we do.

Frequently Asked Questions

How does Web-to-Print specifically increase my profit margins?

The primary margin driver is the reduction of "touchpoint costs." By automating order intake, artwork validation, and procurement data capture, you reduce the administrative cost per job from an industry average of $15–$16 to under $3. This allows you to handle high-volume, low-value orders profitably without increasing your headcount.

Why should I focus on 'fundamentals' instead of complex software integrations?

While many providers offer hundreds of "periphery" integrations, these often result in a "Loss of Focus," high setup costs, and minimal ROI. Mastering the fundamentals - such as a robust connection to your MIS and accurate procurement data capture - ensures that your core production workflow is reliable and scalable. This pragmatic approach delivers immediate, measurable commercial returns.

What kind of procurement data can Vpress capture?

Vpress is designed to capture all essential data required for accurate invoicing and dispatch. This includes, but is not limited to, Cost Centers, Purchase Order (PO) numbers, Department Codes, and specific delivery instructions. This data can be entered directly by the user or pulled from upstream corporate procurement portals (like Ariba or Coupa), ensuring your back-office systems are fed with 100% accurate information.

Can a smaller printer really compete with large enterprises using Vpress?

Absolutely. In fact, automation is the great equalizer. By utilizing Coreprint, a smaller, agile printer can provide the same level of procurement control and brand management as a multinational giant. Because your administrative overhead per job is lower, you can often be more competitive on price while maintaining healthier margins.

Is the "learning curve" for automation worth the investment?

As industry analyst Marco Boer notes, the real cost of automation is the learning curve, not just the software. However, the sooner you move up that curve, the more competitively advantageous you become. Delaying automation only widens the gap between you and competitors who are already reclaiming their margins through digital transformation.

Quick links: The Profit Paradox: Is Your Web-to-Print Strategy Scaling Your Margin - or Eroding It?

Table of contents

Share this article