Services

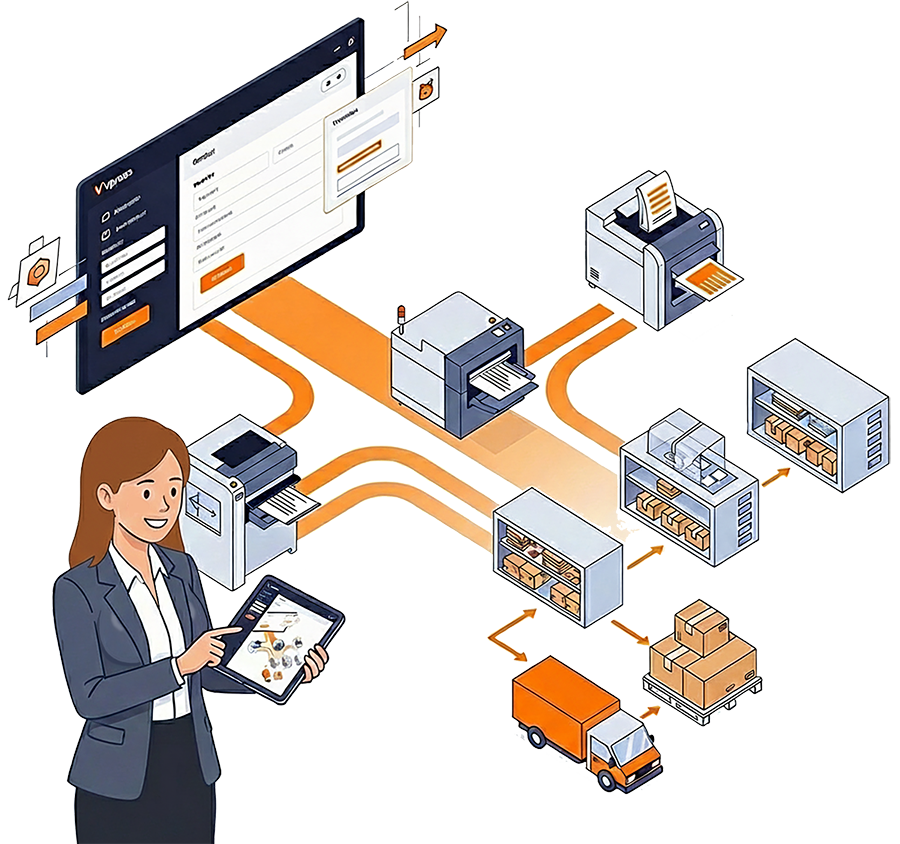

Delivering End‑to‑End Web‑to‑Print Automation

In today's competitive Web to Print (W2P) market, taking orders online is merely the starting point. Achieving genuine, sustained profitable growth requires end-to-end process automation - seamlessly connecting your W2P store with your physical print manufacturing operation.

The Engine of Automation: Maximising Web-to-Print Efficiency

Automation starts with streamlined input, delivering measurable benefits instantly from your online print portal.

Zero Data Entry Errors & Improved Quality

Coreprint validates all critical job parameters (quantity, size, substrate, finishing) and financial details at the point of order. This eliminates manual keying, guarantees error-free data flow into your MIS, and ensures improved production quality from the outset.

Instant Workflow Routing & Maximum Speed

Specific, automated job tags are generated upon order acceptance, guiding immediate, accurate workflow routing and machine allocation. This removes manual job queuing and accelerates time-to-production for maximum manufacturing speed.

Eliminate Pre-Press Overhead

Files are automatically generated to the required specification, providing guaranteed Print & Production Ready Artwork with every order. This completely eliminates manual pre-press validation, file handling, and drastically reduces the cost-per-job associated with delays and rework.

Zero-Touch Production: Automation Driven by Coreprint W2P

The objective is clear: moving a print order from acceptance to despatch with minimal human intervention. The key is for the Web-to-Print platform to deliver rich, production-specific data to every connected business system - from ERP to Logistics. This guarantees efficiency, reduces cost-per-job, and scales your capacity.

Customer Relationship Management (CRM)

Submitting rich order analytics transforms your CRM from a contact list into a powerful sales tool. Enables predictive reporting, targeted retention campaigns, and enhanced marketing automation.

Workflow & MIS Systems

Production specifics (e.g, Digital, Laminated, Spot UV, Saddle-Stitched) instantly route the job. This bypasses manual job queuing, enables machine scheduling, and automates decisions based on capacity and material availability.

Warehouse Management & Stock Control

For stock and pick-and-pack orders, Coreprint synchronises live stock data with your WMS. This delivers real-time inventory accuracy and accelerates efficient warehouse logistics.

Procure-to-Pay (P2P)

Seamless integration into enterprise e-procurement platforms (e.g. SAP Ariba, Coupa) via the PunchOut process. This allows Coreprint to extend the operational scope of the P2P platform while strictly adhering to the financial control and process mandates of the centralised system.

Shipping & Logistics Aggregators

Provides live carrier pricing from multiple services (e.g. DPD, UPS, DHL) directly at checkout. Submits critical parcel data to automate label generation, customs documentation, and integrated customer tracking.

Accounting & Financial Control Systems

Validates financial requirements (e.g., Purchase Order numbers, Cost Centre codes) during order placement, and submits this data to automate client recharging, cost allocations, and payment reconciliation processes.

Ready to Unlock TrueWeb to Print Automation?

Coreprint from Vpress provides the deep Web to Print integrations you need to secure your future in print automation.

Book a demo today and see how our specialists can help you deliver maximum print efficiency and profitability

Frequently Asked Questions

What is "Zero-Touch Printing" and how does Coreprint achieve it?

Zero-Touch Printing (or Lights-Out Production) refers to the ability to move a print order from online acceptance through to manufacturing, packing, and dispatch with minimal or zero human intervention. Coreprint achieves this by providing rich, structured production data and guaranteed print-ready artwork to all downstream business systems (MIS, Workflow, Shipping), allowing them to automate their processes based on reliable, validated inputs.

How does Coreprint's integration differ from basic W2P ordering?

Basic Web-to-Print often stops at sending an order notification. Coreprint delivers deep integration by providing actionable, machine-readable data (including specific Workflow Routing Tags) that systems like your MIS or ERP can immediately process. This depth enables true end-to-end automation, eliminating costly manual steps like pre-press correction, data entry, and job scheduling.

Which major e-procurement platforms does Coreprint integrate with?

Coreprint is built for enterprise-level compliance and integrates seamlessly with leading Procure-to-Pay (P2P) platforms, including SAP Ariba and Coupa, among many others. We utilise the PunchOut process to extend the print ordering scope of these platforms while strictly adhering to all centralised financial control and process mandates.

How does automation specifically lead to better production quality?

Automation enhances quality primarily by eliminating human error. Coreprint validates all order parameters (quantity, substrate, finishing) at the point of order, guaranteeing zero data entry errors in your production systems. Furthermore, the guaranteed Print-Ready Artwork ensures files are correctly generated to specification every time, preventing quality issues and rework associated with manual file correction.

Is Coreprint a replacement for my existing MIS or ERP system?

No. Coreprint is a specialised Web-to-Print platform designed to be the highly efficient front-end for your existing infrastructure. Our core strength is deep integration: we are built to feed perfect data and files into your existing mission-critical systems (MIS, ERP, WMS, CRM), maximising the value and lifespan of your current technology investment.